Eco-Printing: Case Study

Process Overview

Eco-Printing is the process of printing natural elements (such as flowers and leaves) onto fabric. After gathering natural materials, I tested different mordanting methods (fabric finishing methods, helps with color intake and retention) to see what worked best. The mordants I tested were calcium carbonate (chalk), alum, soy, and combining alum and chalk. I also tested printing without mordants as a control method. After the fabrics were treated with mordants, I let them cure (i.e., sit untouched in a dark space) for 5-7 days. Once this was complete, I let my fabrics scour in cold water for 2-3 hours before printing. Then, I placed the materials onto the fabrics, hammered them down, and rolled them up. Finally, I steamed the fabrics for anywhere from 1-3 hours, then released the bundles, rinsed them, and hung them to dry.

Eco-Printing Results

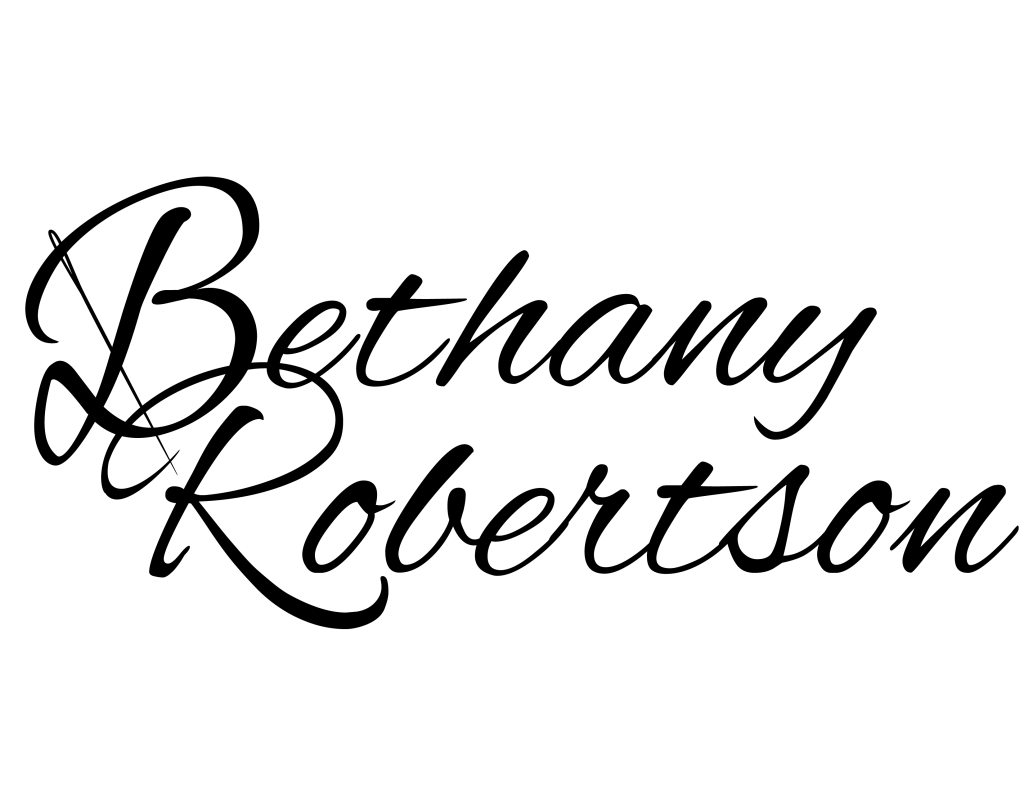

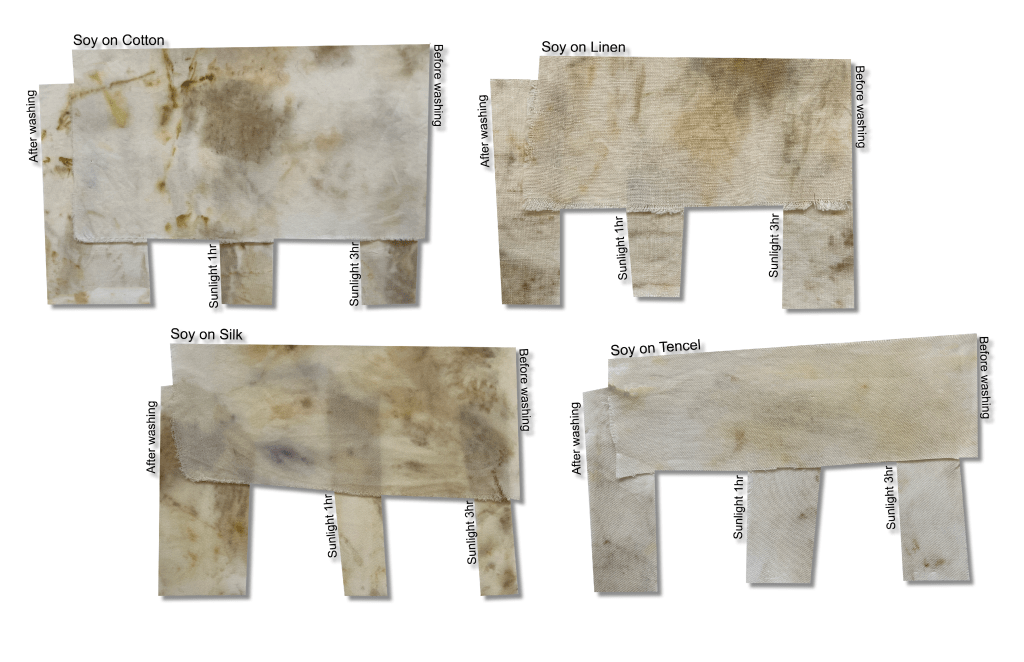

During the first round of tests, I tested different mordanting methods and color fastness. I washed pieces of each swatch after letting them cure for 1 week and tested them in sunlight at different intervals to test color fastness. Below are the results.

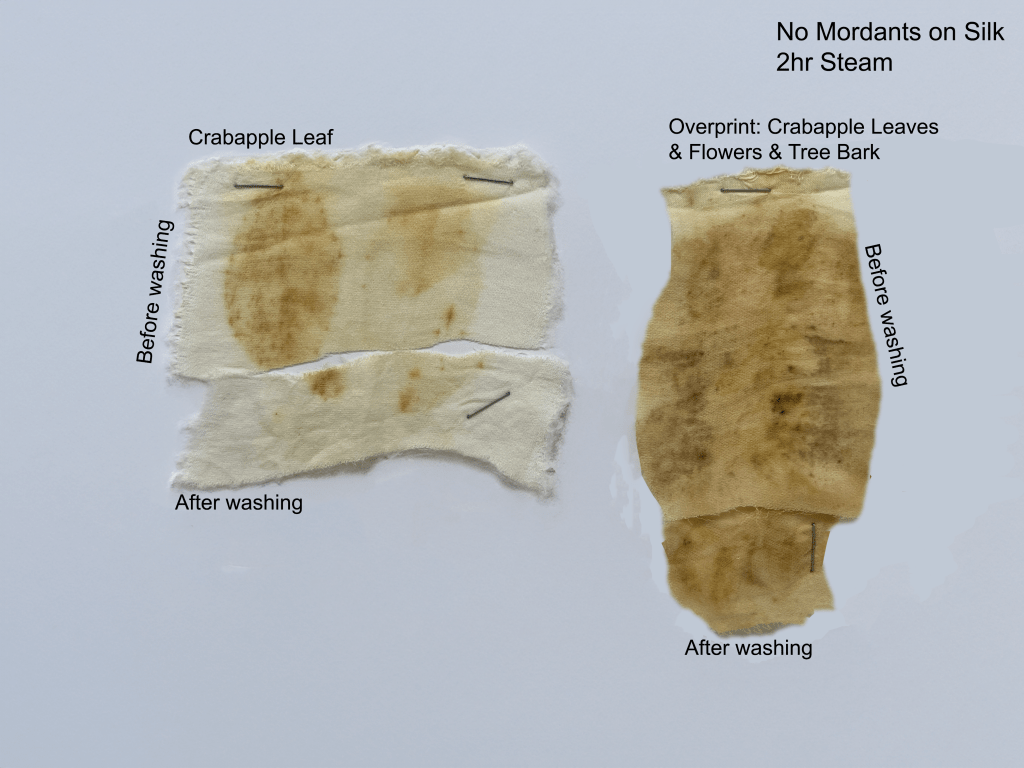

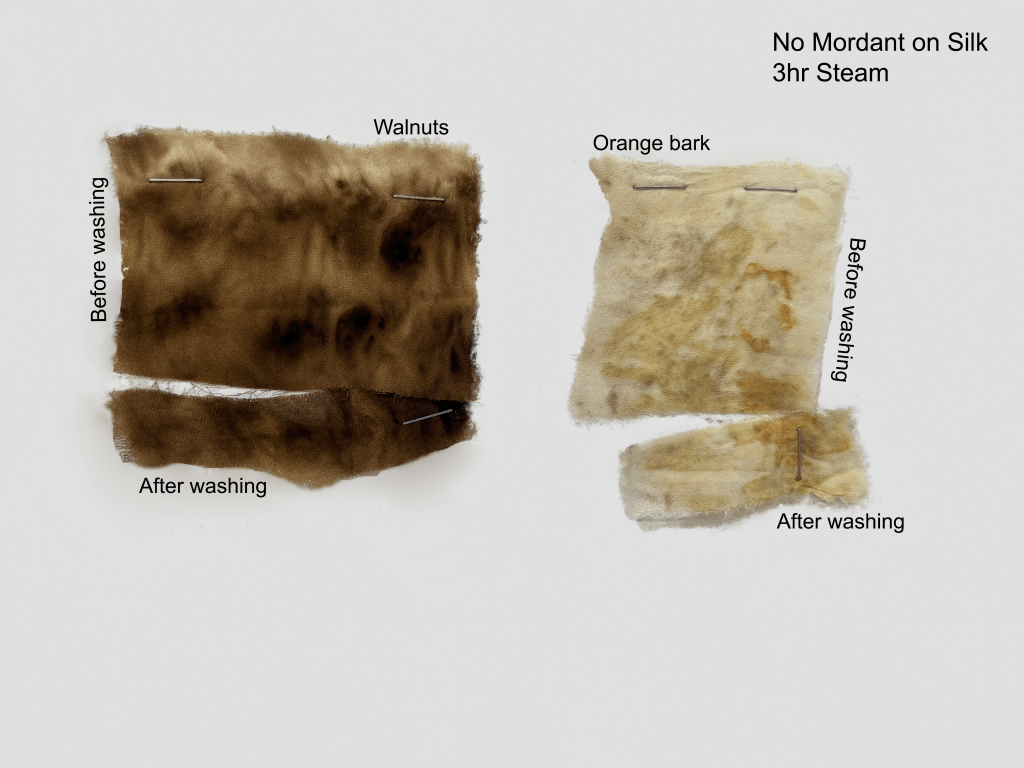

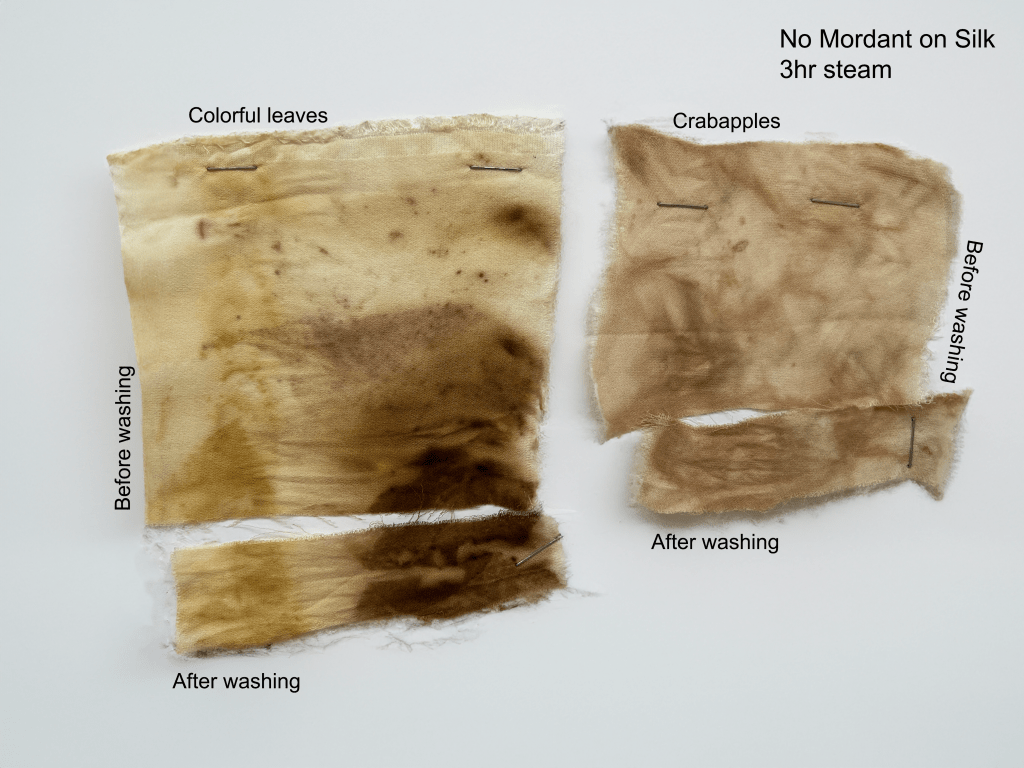

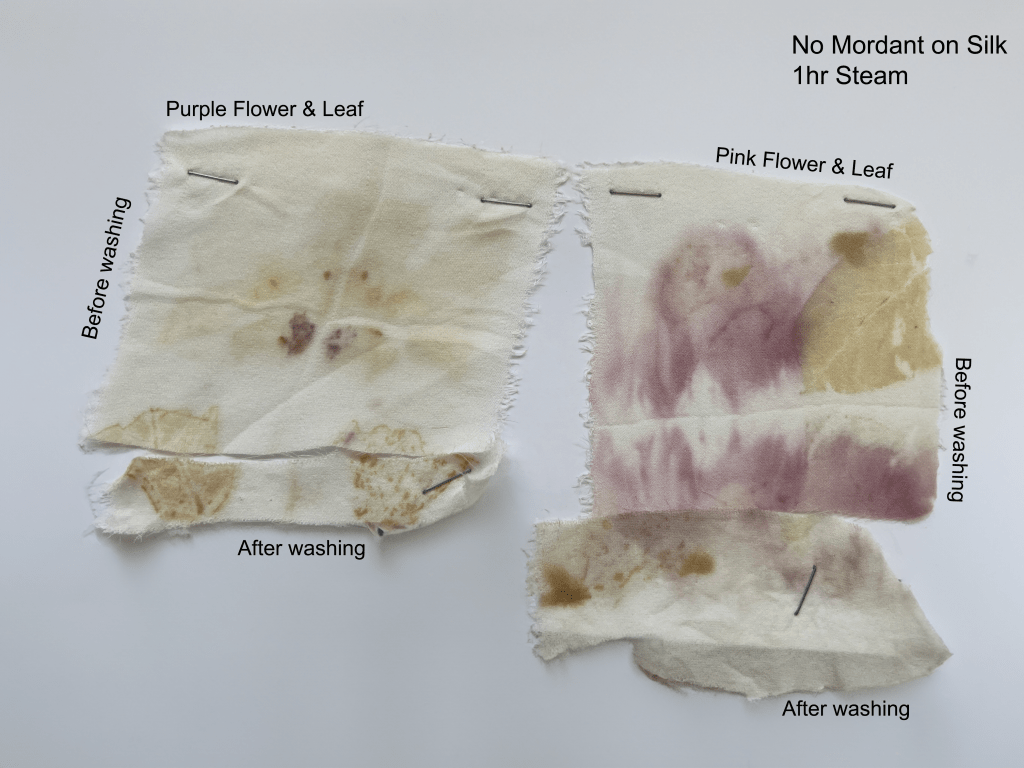

The alum & chalk mordanting method was by fair the most successful when it came to color retention and intake on cotton, linen, and Tencel. Soy also had surprisingly good results on cotton and linen, since it is known for being a weaker method of mordanting. Silk retained and took colors the best out of all the fibers. However, all mordanting methods did change the colors the silk fabric took. Overall, no mordanting method on silk worked the best for retaining and intaking natural colors. Alum on silk did well, but it does change the color intake to be more brown and yellow.

Additional Tests

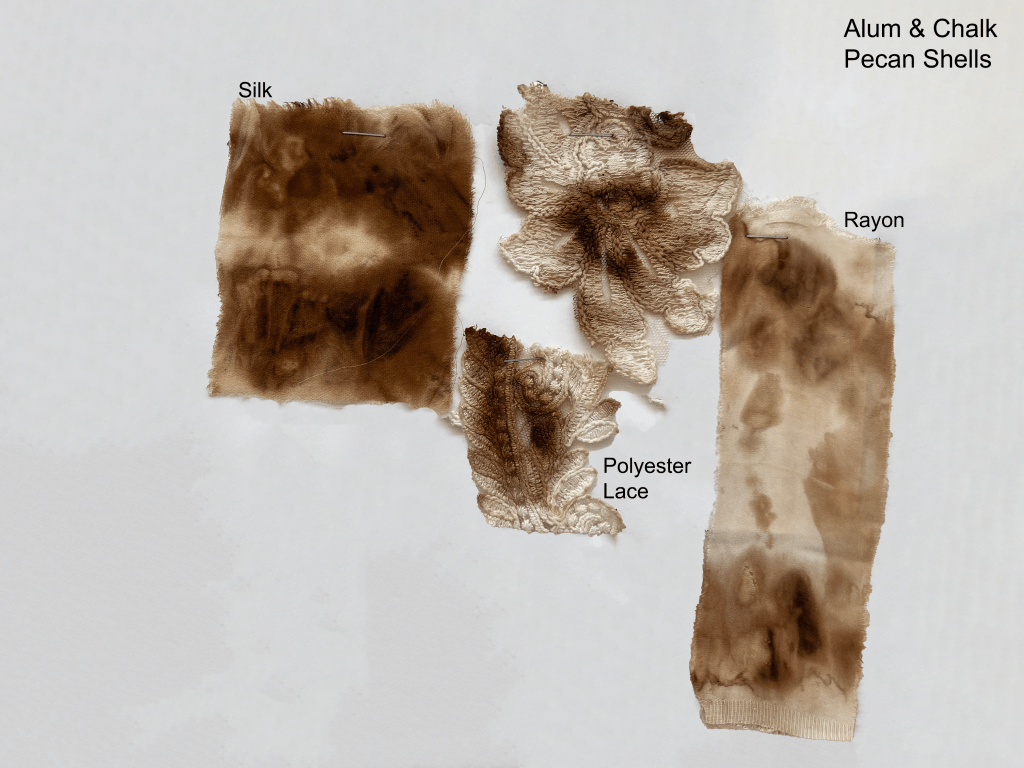

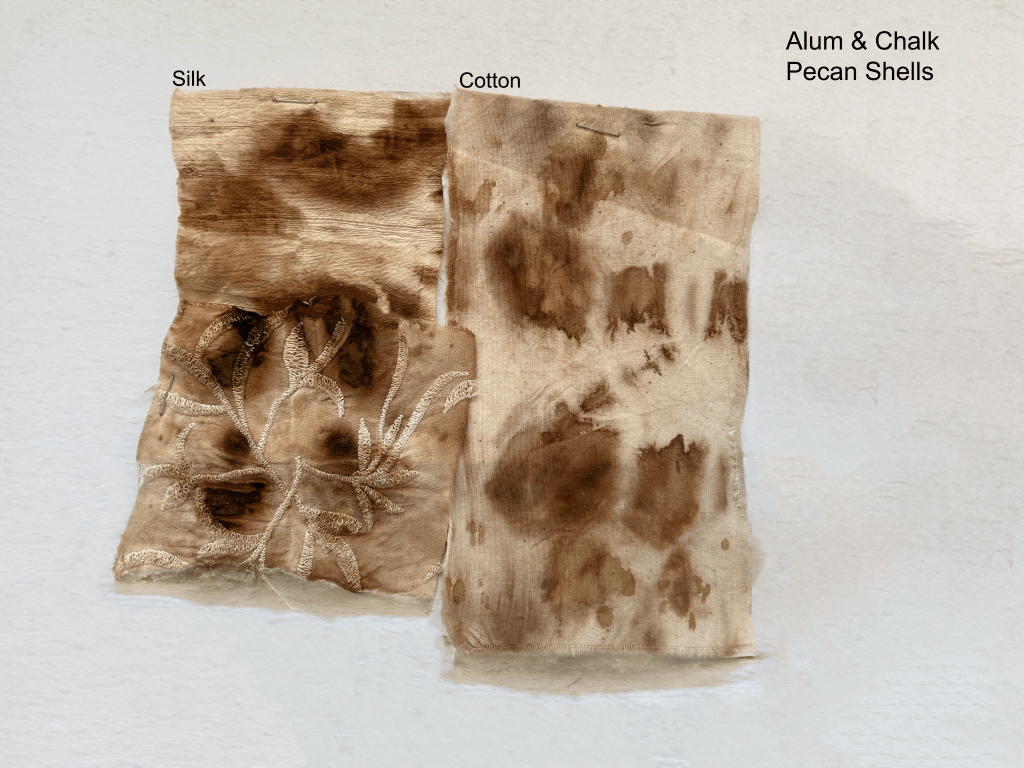

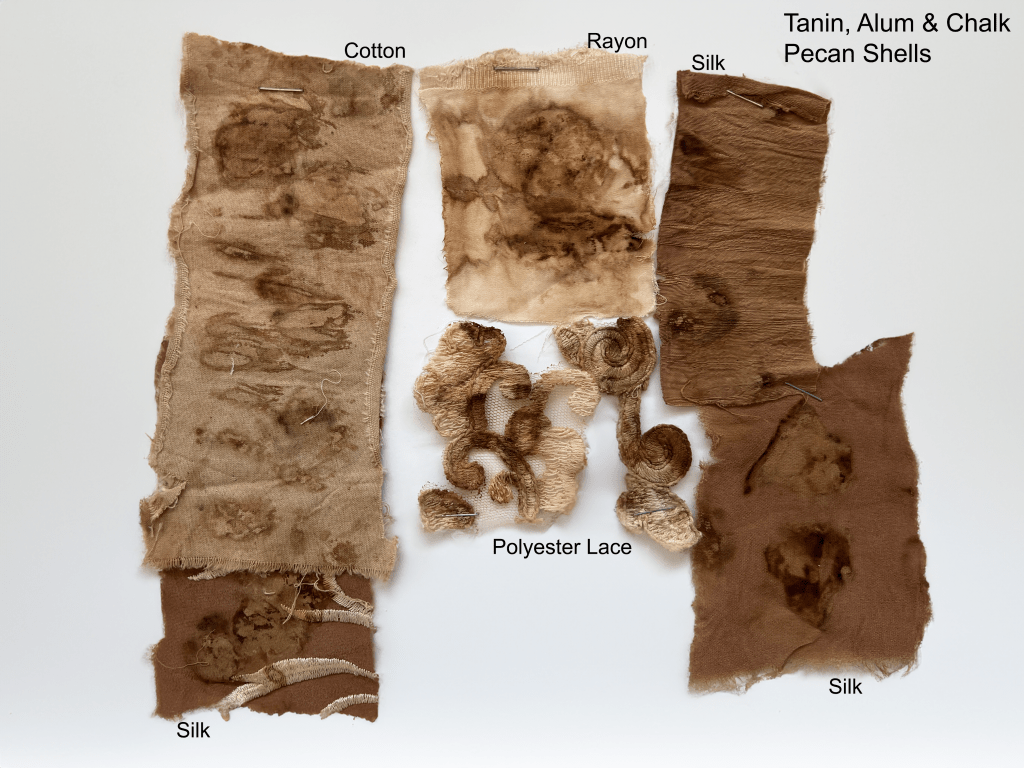

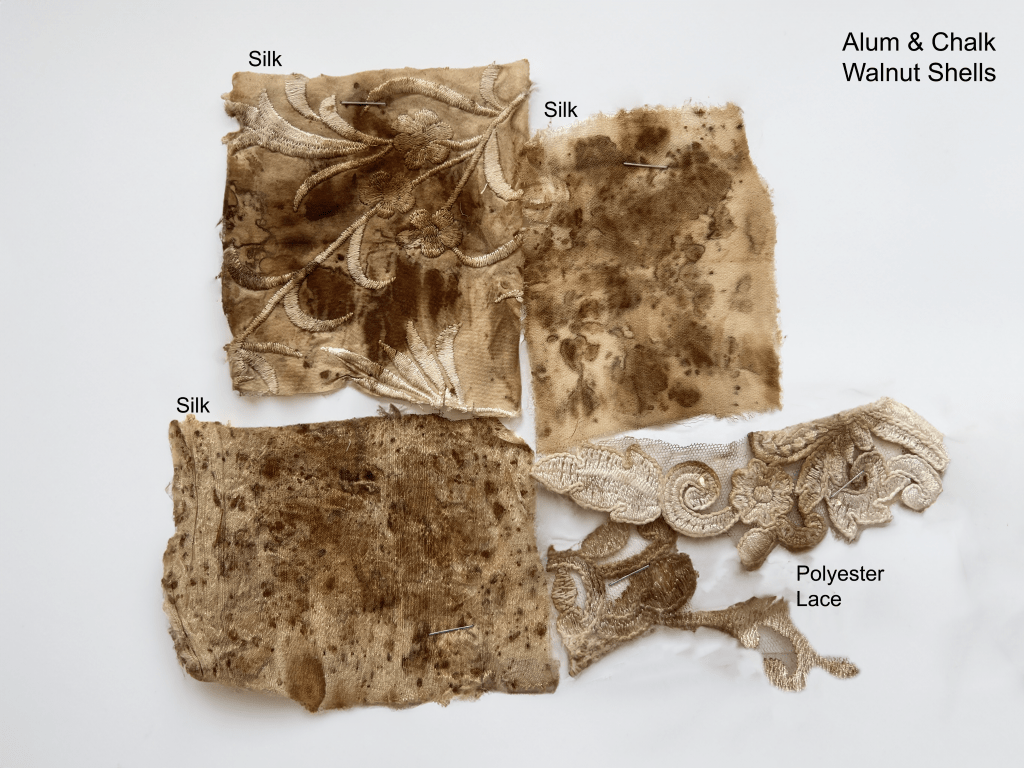

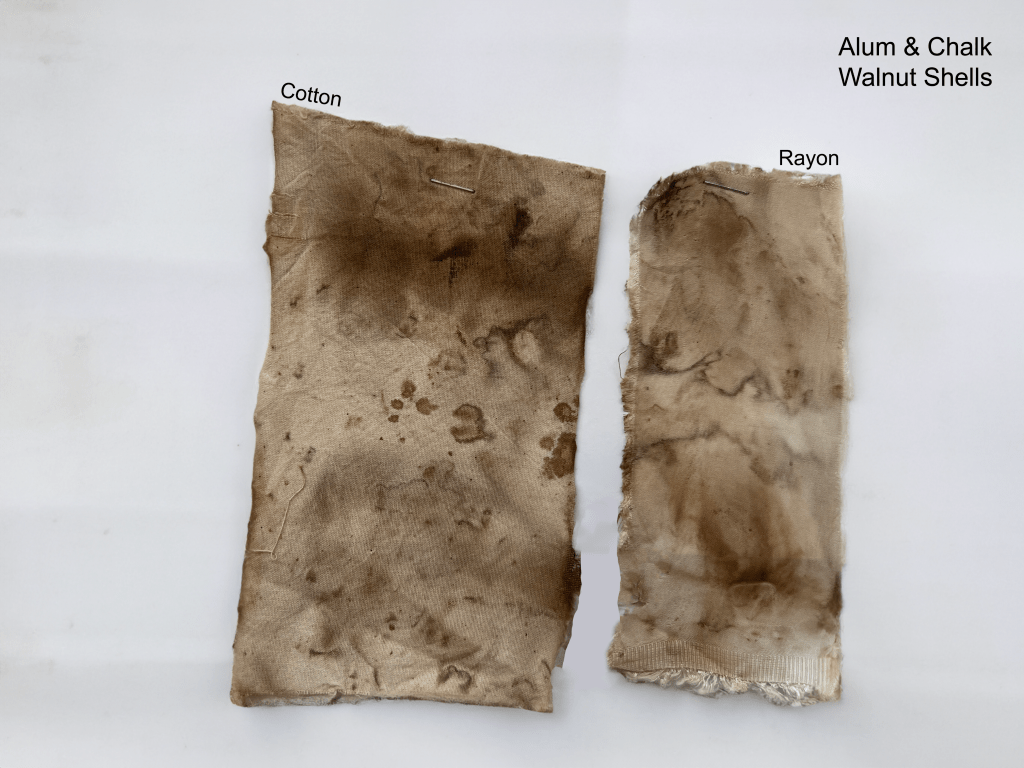

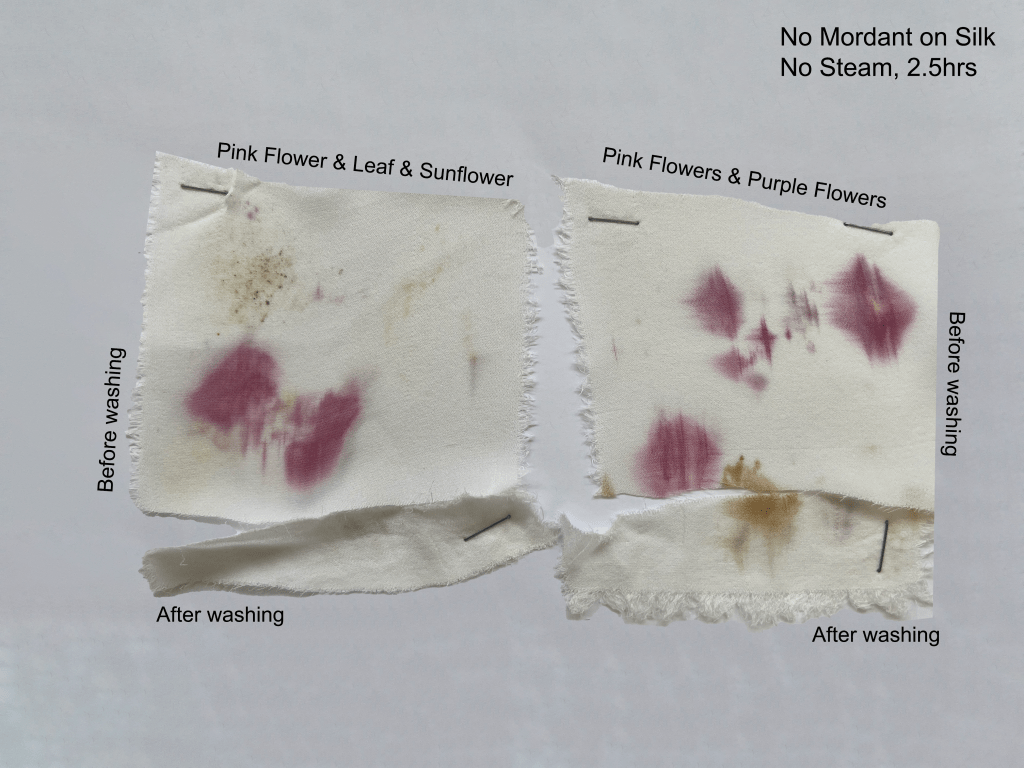

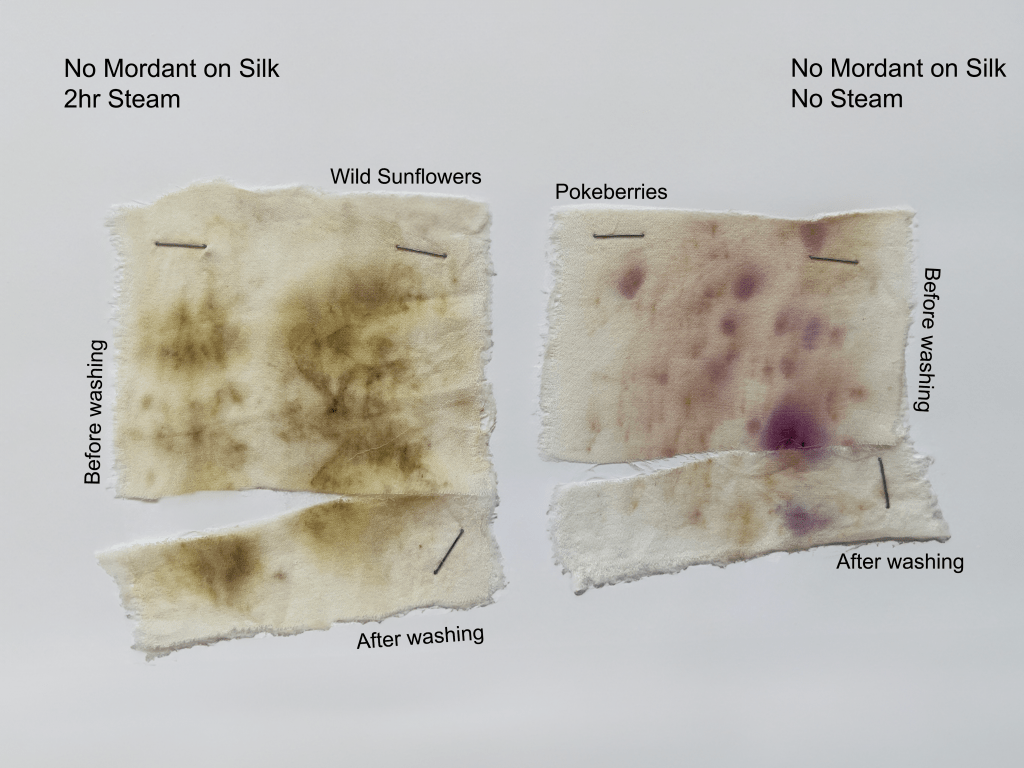

I was curious what other colors I could achieve naturally through eco-printing. So, I tested eco-printing walnut and pecan shell scraps onto different fabrics. I tested a few different mordanting methods for these, including alum & chalk and tannin, alum, & chalk to see what colors turned out the best. I also tried different materials on silk without a mordanting method, and a couple different flowers on silk without steam to see if I could retain their original color. Below are the results.

The nut shells took surprisingly well on the lace, given that the lace was polyester. Tannin, alum, & chalk was the best mordanting method for nut shells on cotton, rayon, and polyester. On silk, the tannin turned the fabric to be very brown, to the point where it was hard to see the color of the shells. Silk takes color the best out of all the fibers and eco-prints best without mordants. I tried eco-printing on silk without using steam to see if I could retain the pink color of certain flowers, but the color did not hold without steam once washed. Thus, most pink flowers turn purple or yellow when steamed; it all depends on the types of flowers used.